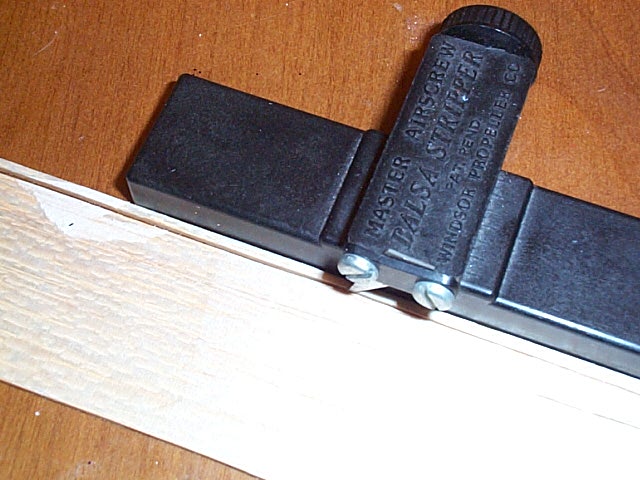

There are basically two methods

of cutting your own stripwood. The first method is to buy a balsa

wood stripper. These devices use a razor blade or X-acto knife blade

to cut the wood to a preset thickness as you slide the cutter along the

length of the sheet of balsa.

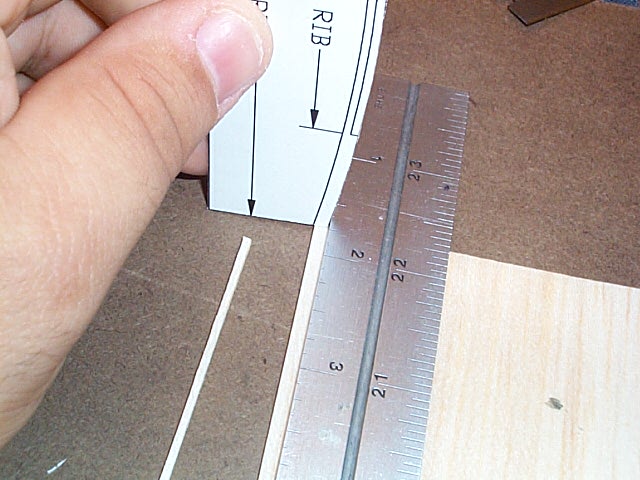

If you are unable to find

a wood stripper like this at your local hobby shop, then you can cut wood

the 'old fashioned' way with a straightedge ruler and a single edge razor

blade. To do this you simply lay a ruler down on the piece of wood, set

the width of the cut, and then cut the strip off with the razor blade.

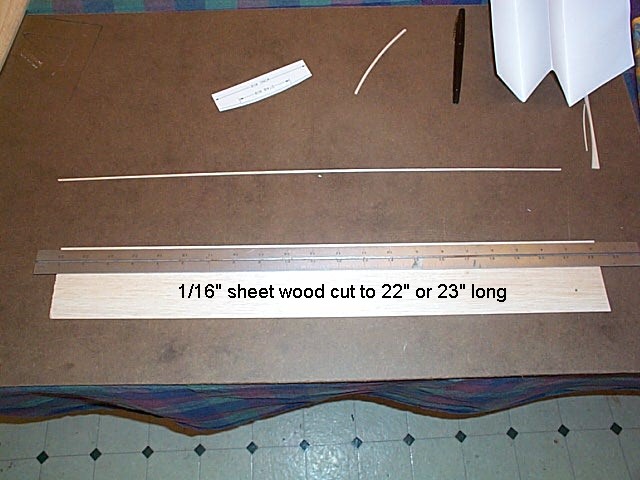

This photo shows me using the wing rib template to set the width of the

wing spar cut (1/8" wide). I would suggest buying a 24" long ruler, and

cutting off the sheetwood to 22" or 23" long.

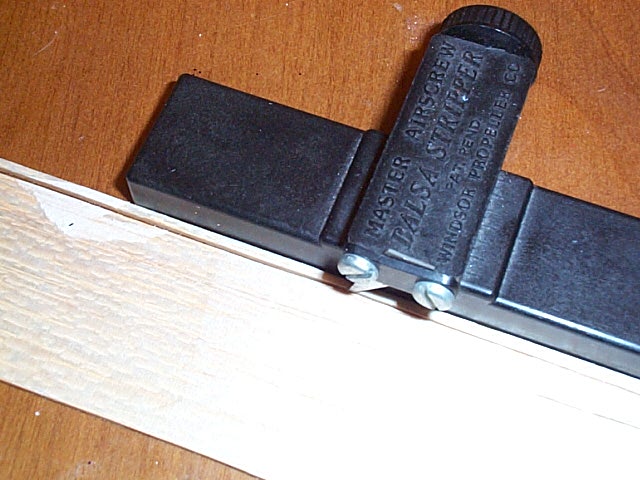

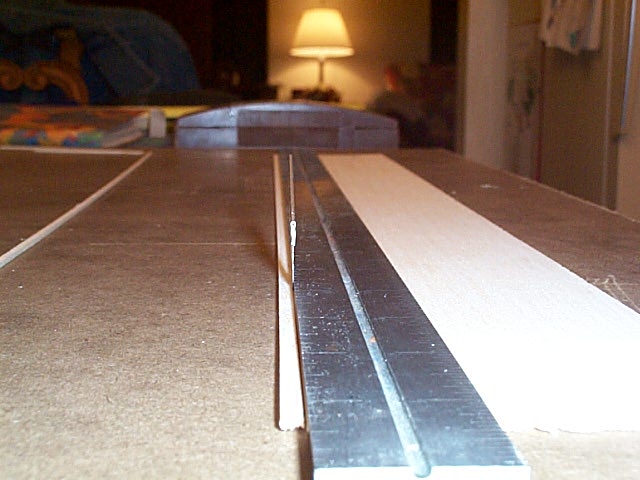

Here is the ruler preset

to width and ready to cut.

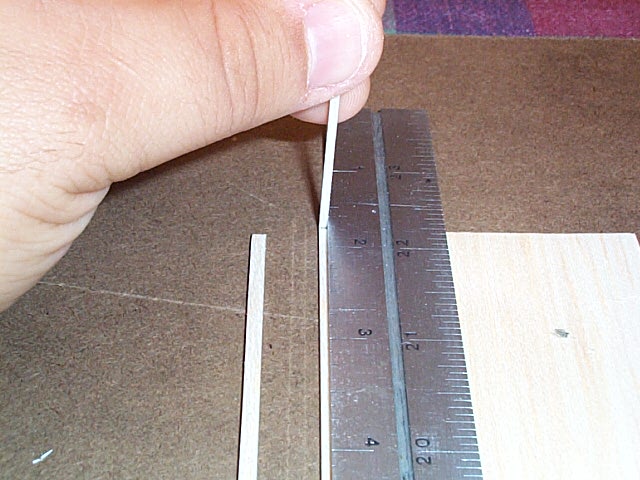

Now cut down the edge of

the ruler, using it as a guide, to cut your strip of wood. Make sure that

the razor is vertical when cutting.

After you cut the wing spars,

you can cut out the 1/16" sq. stab wood in a similar manner. You can use

the thickness (1/16") of the wing spar as a guide to setting the depth

of the cut.

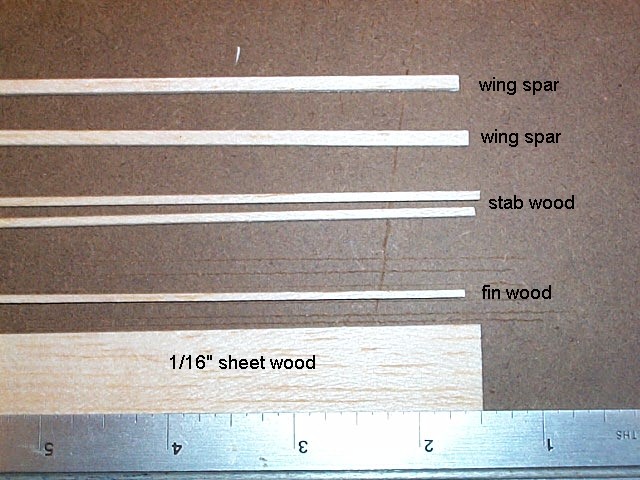

Here are the cut strips.