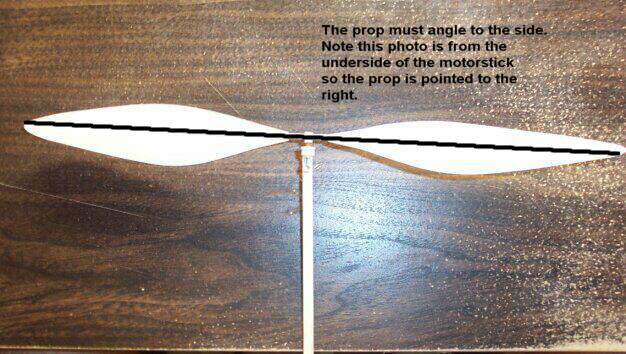

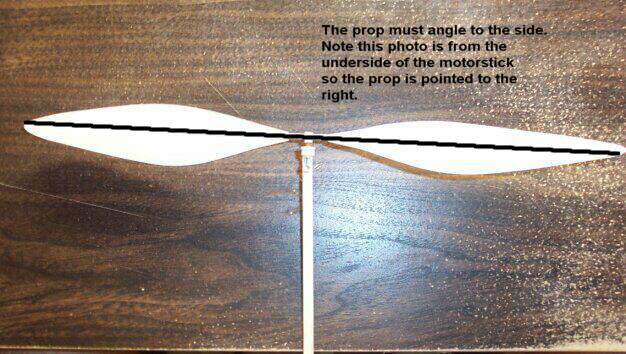

Turn the motorstick so the

BOTTOM is facing you, and see if the prop hanger has side thrust. Note

in the picture that the left side of the propeller is higher than the right

side. This is the side thrust that helps to pull the nose of the model

to the left when flying to make it circle, the proper amount is around

2 degrees.

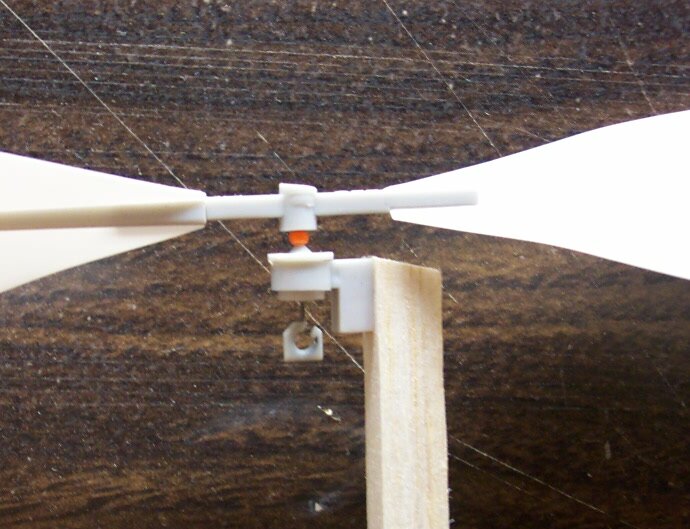

Apply a small amount of glue

around the prop hanger. Once it dries, remove the prop from the prop hanger

and wrap the nose with some thread. Apply glue all around the thread. The

thread helps protect the prop hanger from breaking off of your model. This

can happen during handling, when the model hits the ceiling, or when the

model lands on the floor.

Glue the rear hook to the

back of the motorstick and wrap with thread the same way the nose bearing

(prop hanger) was.

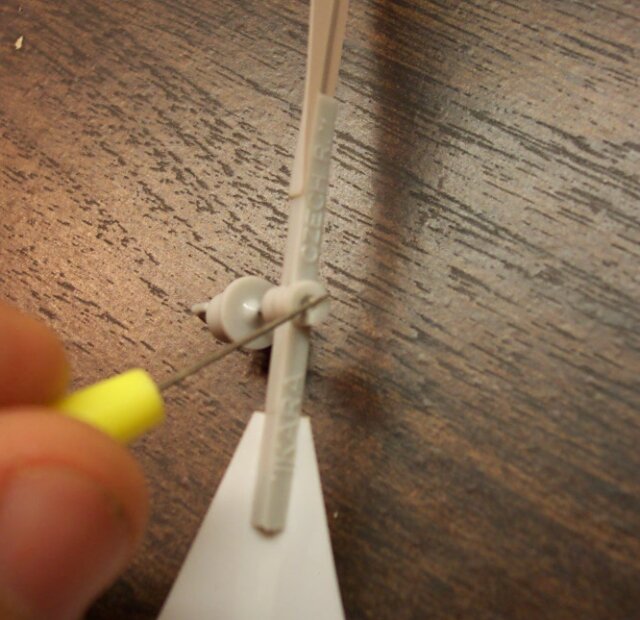

Now we need to prepare the

propellor. First place a SMALL drop of superglue

down the shaft hole on the prop hub. the purpose is to glue the wire shaft

to the hub. Be careful no to let the excess superglue run down the wire

shaft into the plastic bearing, otherwise the prop may not rotate.

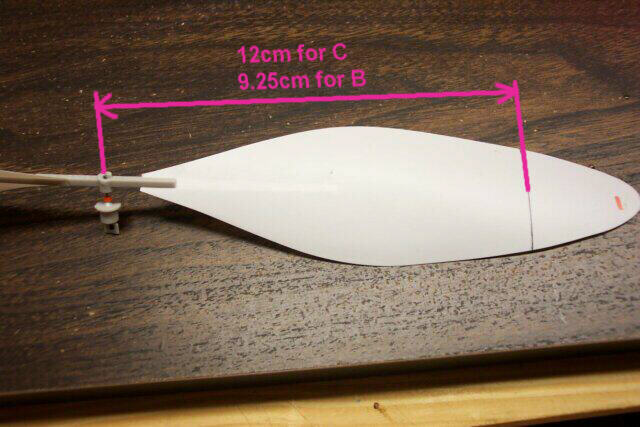

Draw a line on the prop blade

which is half the diameter allowed for the division you are flying. Division

C props can be 24cm in diameter, so make the line 12cm out from the center

shaft of the propellor. For Division B models the maximum allowable diameter

is 18.5cm, so half of that is 9.25cm.

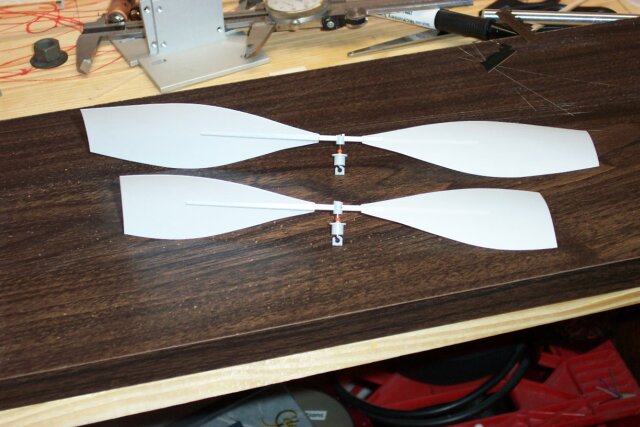

Use a pair of scissors and

trim off the tips of the propellors. The upper propellor is for the Division

C model, and the lower prop is the Division B model.