Both my Division B and C models flew on a 14" loop of .105" wide x .039" thick Tan II rubber with 1600 turns. Normal rubber is .042" thick, and since the rubber I was using was .039" thick, the width had to be increased to compensate for the thinner thickness. Note that the 14" long, 2 gram loop of my .039" thick by .105" rubber weighs as much as a 14" long, .042" thick rubber .100" wide. This is a very important concept as the key factors to a motor are only the length and weight. Width is something we measure as a reference, but should not be used as a final factor in your motor sizing, only length and weight.

In an event like this, the weight of the rubber is always 2 grams. So the length is really the other controlling variable. Because of variances in manufacturing must be accounted for, the width needs to be adjusted to achieve the proper length. For example, the rubber motor I used was 14" of .105" wide rubber .039" thick and weighed 2 grams. Say a different batch of rubber is .042" thick, and when cut .100" wide and 14" long will weigh the same 2 grams. They will both take the same turns even though the width of one is .105" and the other is .100". The model will fly the same with either loop. The point I am trying to make is do not get too caught on rubber width, especially when comparing to other people's models, be more concerned with loop length and making sure the loop is as close to 2 grams as possible.

Since the weight is limited,

the thinner the rubber the longer the loop will be and vice versa. Here

is a rubber chart to help you make your motors. This chart gives you the

approximate length of a 2 gram loop of rubber (.042" thick) with o-rings.

These values are approximate and really depend on the specific type of

rubber you have. Some rubber is thicker and has slightly different densities

than others, but this will give you a starting point. This chart also gives

a 'safe' and 'maximum' amount of turns expected for each of the different

sizes for Tan II type rubber. Your batch of rubber may be different. It

is highly recommended that you take make a few loops of rubber up and wind

them until they break. That way you know for sure how many turns your batch

of rubber can handle.

| Rubber width (inches) | Loop length for 2 grams

(inches) |

Safe number of turns | Maximum number of turns | Safe turns per inch loop | Max turns per inch loop |

| .080 | 18 | 2095 | 2335 | 116.4 | 129.7 |

| .085 | 17 | 1920 | 2140 | 112.9 | 125.8 |

| .090 | 16 | 1755 | 1955 | 109.7 | 122.3 |

| .095 | 15 | 1605 | 1785 | 106.8 | 119.0 |

| .100 | 14 | 1455 | 1625 | 104.1 | 116.0 |

| .105 | 13 | 1305 | 1450 | 100.4 | 111.5 |

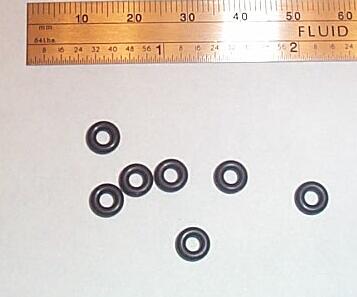

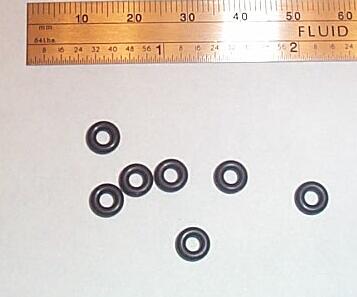

I would highly suggest using

a pair of o-rings on your motor to help with the winding and flying. For

the Science Olympiad models you can use a -005 rubber o-ring. You may be

able to find these at a hardware store but if you have difficulty then

I would buy some from a tool supply house or hydraulic/pneumatic fitting

supplier. I would suggest McMaster-Carr, part number 9452K13, Buna N O-ring

size -005, $3 per 100pcs.

www.mcmaster.com

Ph: 330-995-5500

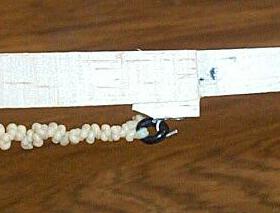

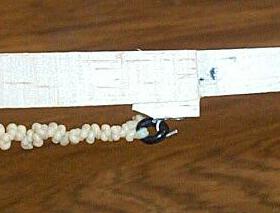

You may find your have troubles

with using this type of o-ring with the Ikara prop shaft. You may wish

to try using a piece of Nylon 6 rigid tubing. I use 5/32" O.D. x .106"

I.D. semi-translucent rigid nylon tubing which is available from McMaster

Carr as well, Pt# 5173K7. The tubing is sold by the foot (about $.15/foot),

and should be cut into 1/32" wide slices using a razor blade. This tubing

is a rigid plastic, it is very lightweight, strong, and a 12" piece will

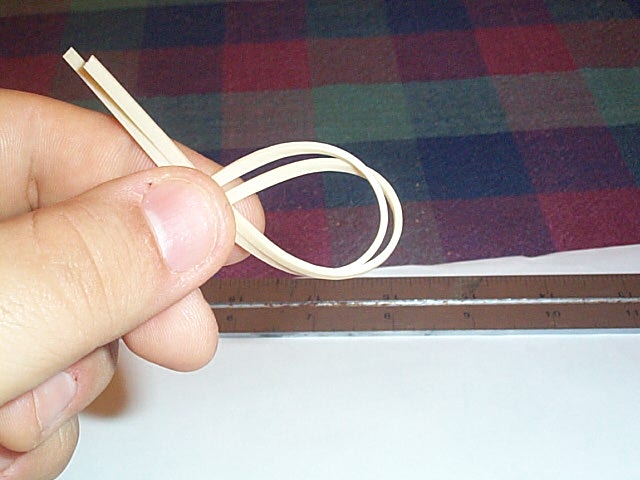

make 100's of o-rings. Here is a photo showing a tied motor with these

o-ring on it.

Now to back to making a motor!.

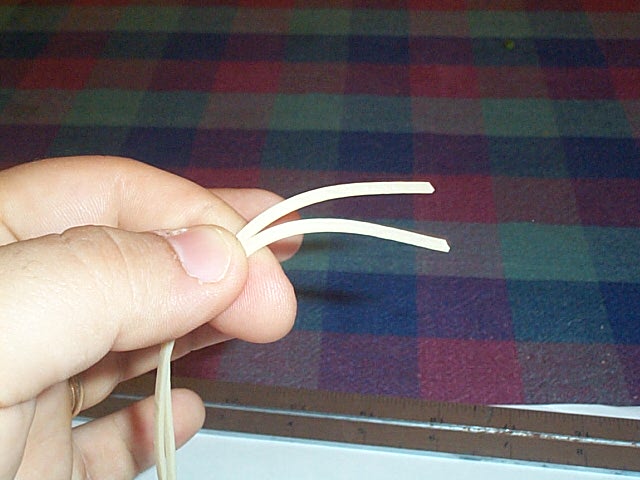

Cut enough rubber to make

a loop about 3/4 to 1" longer than the desired final length. Slide the

rubber strip into the o-rings and then tie a knot as shown in the picture

sequence below.

Now pull the rubber slightly

to create a loose knot. If you have a scale, now would be a good time to

check the weight of the loop. Because there is some extra rubber on our

loop, the motor will weigh over 2 grams, like about 2.05 grams. When we

finish the knot and cut off the excess, the motor should come in just under

2 grams. This process will require a few trial and errors on your part

to see how much weight is subtracted when you do this process.

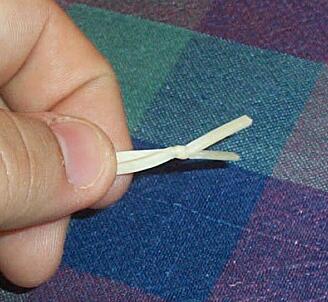

If the rubber weight is too

much loosen the knot a little and shorten the loop and cut off the excess

rubber so that there is again about 3/4 to 1" of excess rubber. If the

loop is 2.05 grams or less then pull the knot tight.

Then tie three overhand knots

into the rubber ends to secure the knot. Pull the knot tight each time.

Then cut off the excess rubber.

The motor is now finished,

check the weight to make sure it is less than 2 grams.