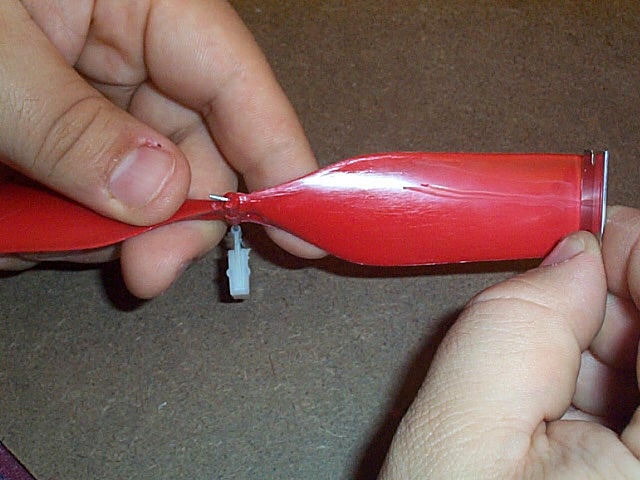

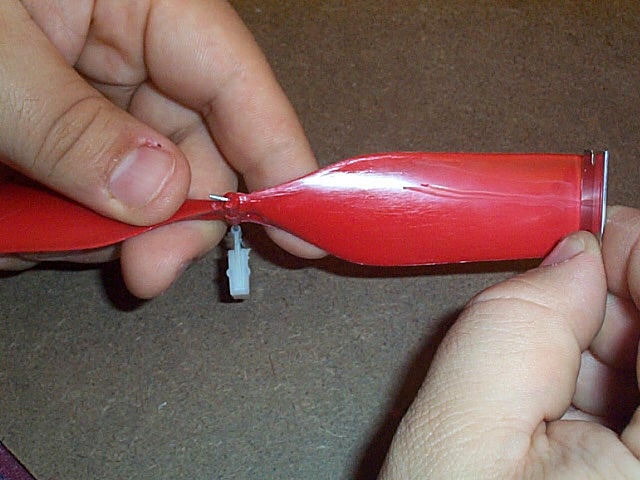

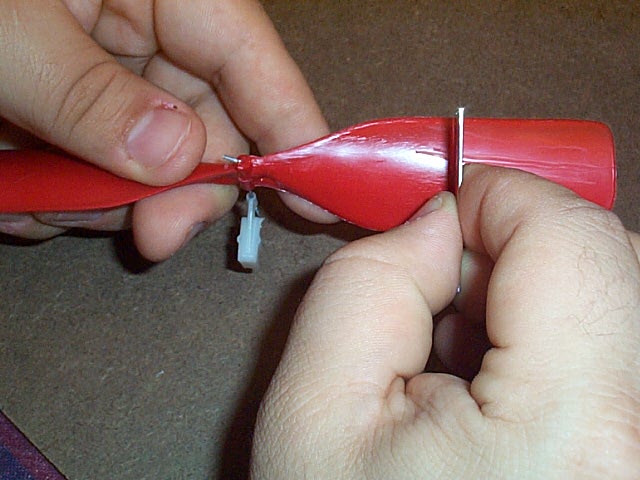

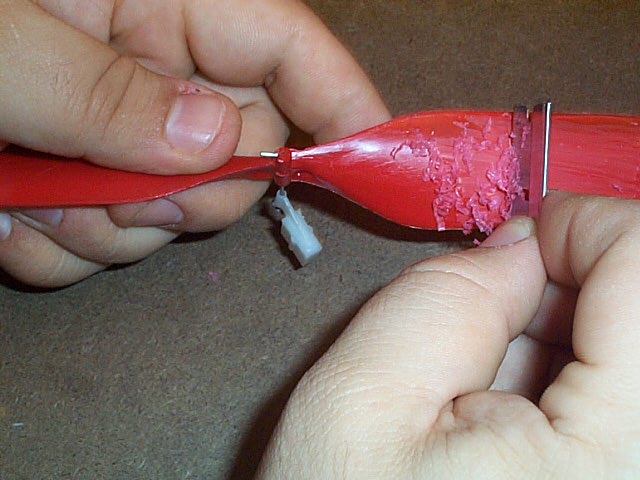

Scraping the prop is easy

to do, it is just time consuming. The procedure is to take a single edge

razor blade and scrape it back and forth over the prop blade. The photo

sequence below shows how this is done. When doing this, you should count

your strokes, do 50 on one blade then switch and do 50 on the other blade.

This helps to ensure that you remove the same amount of plastic off of

each blade so one is not heavier than the other which can cause the prop

to shake when it spins.

The same method is used when

cutting down a larger prop to 20cm. Here is an unmodified 9" prop and next

to it is a 3.5 gram prop which has been scraped down and repitched.

Look at how much excess plastic has been taken off near the hub.

This thicker area of the

prop can be removed by using a round file or a Dremel type rotary tool.

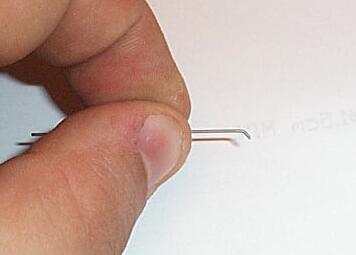

After you have scraped the

prop down to about 3 grams or so, you will have to make a prop shaft. You

will need your round nose pliers, and about a 2" piece of .020 or .025

music wire. First bend a small angle as shown below, the bent piece should

be about 1/16" long.

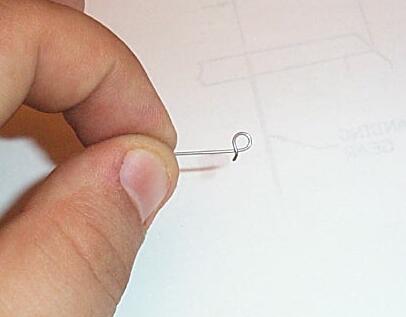

Then use the round nose pliers

and start to bend the hook as shown below.

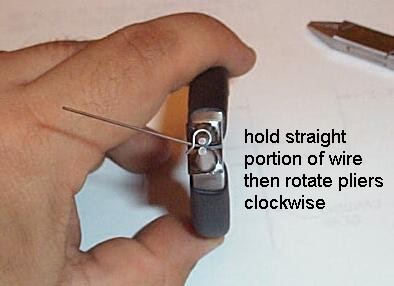

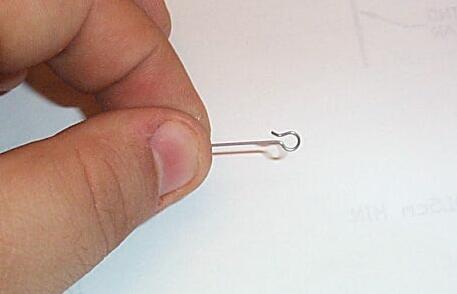

Then continue until you have

the following.

Then use the round nose and

bend the hook back on itself as shown below, and the prop shaft is done.

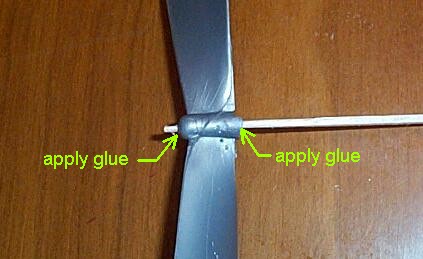

The next step is to glue

the prop shaft into the prop. The hole in the prop is .047" and the

shaft you just made is .020" or .025" diameter. Use a scrap piece

of 1/16" square balsa and round it with some sandpaper, then push it into

the prop. Apply a small drop of superglue on each end.

Then cut off the excess wood.

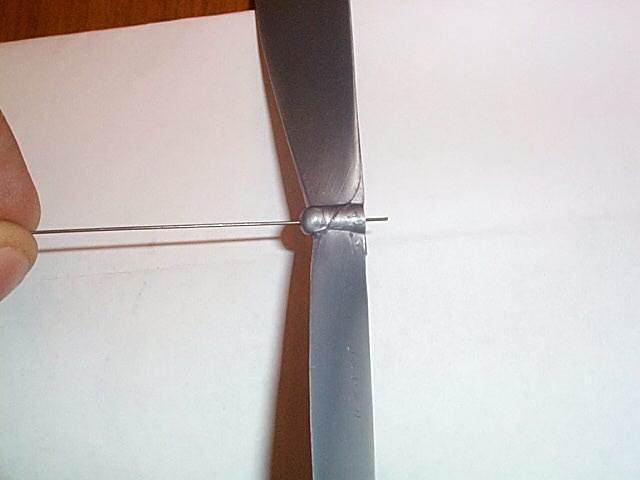

Now push a piece of the prop shaft wire into the balsawood plug. Try to

keep the wire going as straight as possible when pushing it into the prop.

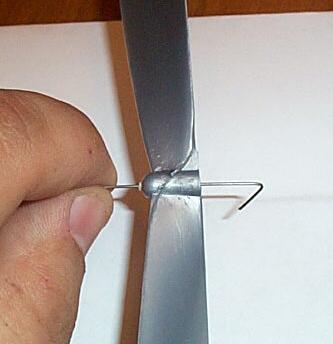

Try to avoid making it crooked

like this.

Then bend the wire back and

then glue it to the prop with a drop of superglue.

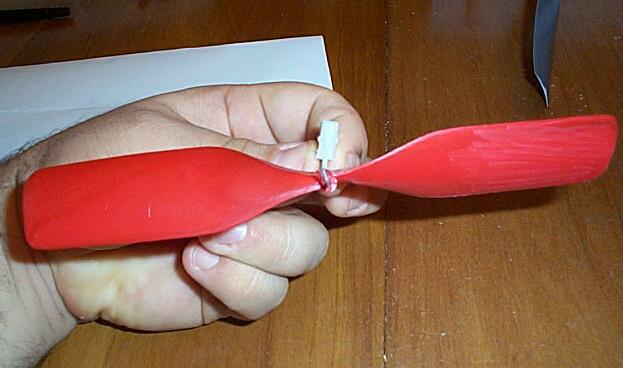

The last thing to check is

whether the prop is balanced. There are two types of balancing, static

and dynamic. Static balancing is checked when the prop is not rotating.

What you are doing is seeing if one blade has more mass than the other.

This is simply done by holding one of the prop blades horizontally and

then letting the blade go. If one blade is heavier, then it will rotate

to the bottom. (if you are not using the red prop assembly then you will

have to place the prop in the thrust bearing first before doing this test).

If the prop is in balance, then the blades will stay horizontal as shown

in the photo below.

If one blade is heavy, then

it will fall to the bottom.

The other type of balancing

is dynamic balancing. This refers to whether the prop is in balance when

it is spinning. A statically balanced prop may not be dynamically balanced.

If one blade has more pitch than the other, then that one blade will create

more lift. The unbalanced lift will cause the prop to shake when flying,

and the model will look like it is vibrating when it is flying. To check

for dynamic balancing, watch the prop spin and hold the model by the motorstick

and feel and look for shaking. Also watch the model fly and see if you

notice some shaking when it is flying. If it does, then look at the prop

from the side when it is rotating. You will see a blurred image of the

prop as it rotates. If you watch carefully you can see when each of the

separate blades come by as the prop rotates. Look at the tip of each blade

as it comes by, each blade should follow in the same path as the previous

blade. If one prop tip is ahead of another prop tip, or one blade is higher

in pitch then the other then you will be able to see two separate prop

shapes as the prop spins. Below is a graphic depicting this and how to

correct the problems.

![]()

Back

to the main page.