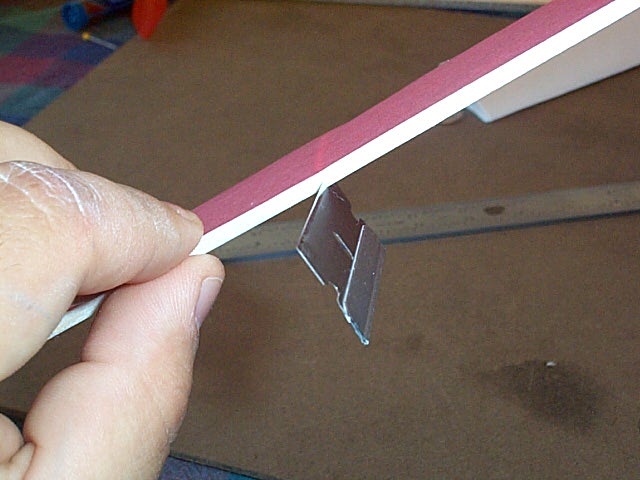

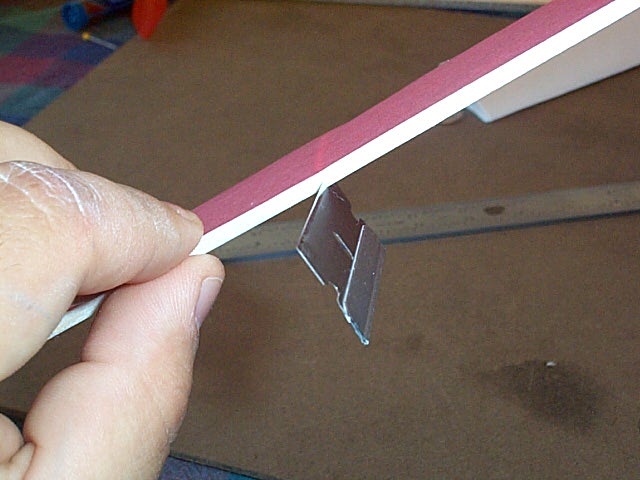

First, take your razor blade

and cut the leading edge wing spar (next to the center rib) about half

way through the spar like you did for the dihedral in the wing tips. Then

bend the wing upwards to crack the wood, like you did for the dihedral

in the wingtips. (Note that the cut is made on the right side of the center

rib as shown in the photo.)

Then lay the wing down on

the table, and place a 1/8" balsa shim under the leading edge spar to hold

the wash-in setting in place.

Place a couple of quarters

on the wing to hold it down on the table. Then apply a drop of superglue

to the crack you made in the spar by the center rib, and then apply the

accelerator. Let it sit for about one minute to dry.

Remove the weights, and then

lift the wing off the table (it may be necessary to slide

the razor under the spar to cut it free from the table). The wing should

now have 1/8" of wash-in. (see photo below, and how the trailing edge is

progressively lower than the leading edge as you move to the right.)

Now is also a good time to

fill in the gaps at the dihedral breaks. Place a small drop of glue into

the gap and apply accelerator to cure it. This will make the wing tips

stronger, and prevent them from breaking when the model is flying and when

it flies into something (it will happen!).