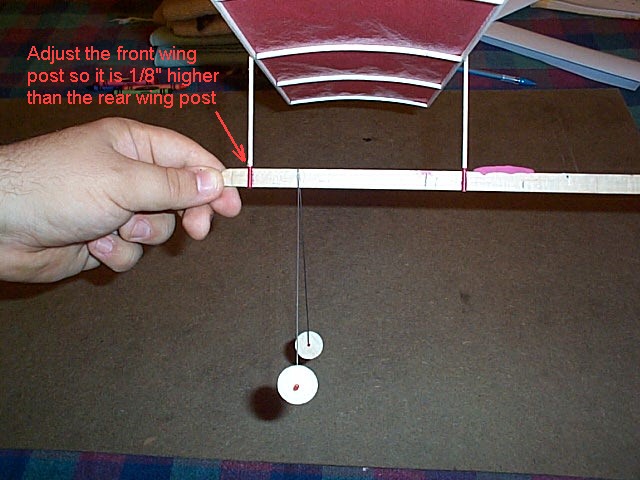

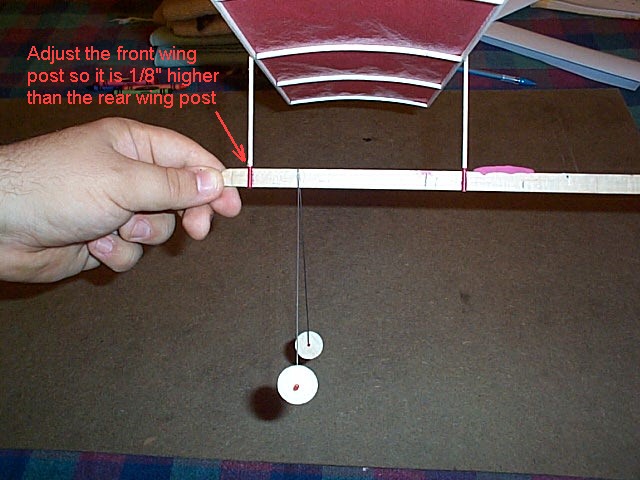

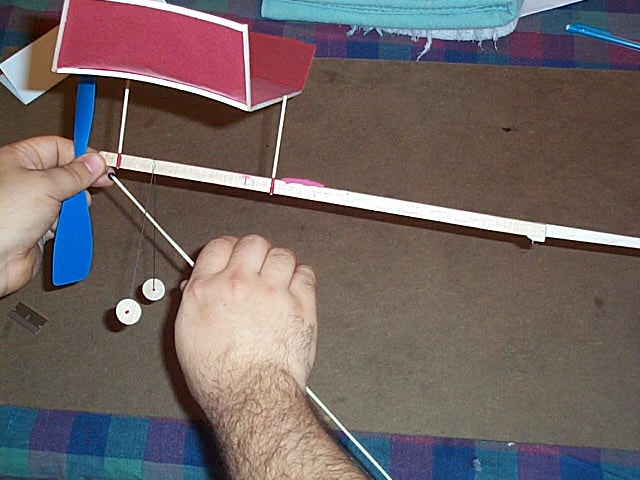

Raise the front wing post

1/8" higher than the rear wing post.

Look down the model from

the front and check to make sure the model looks OK.

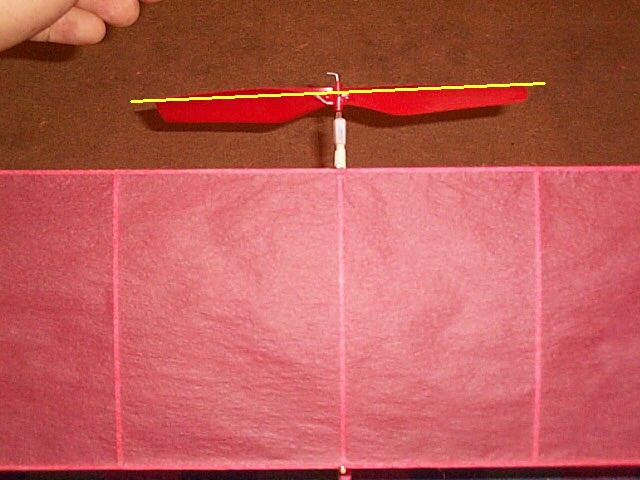

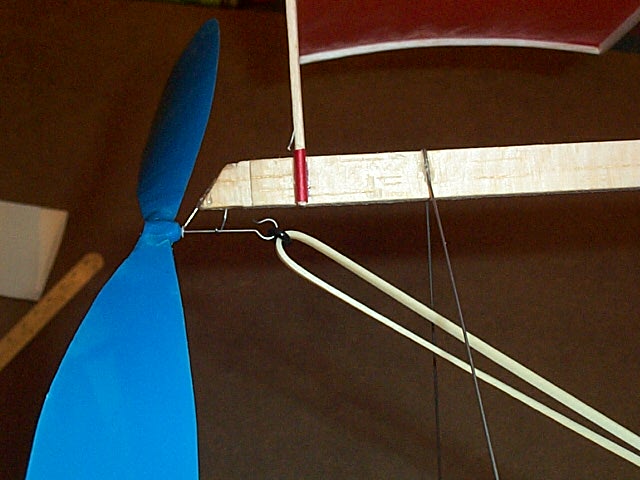

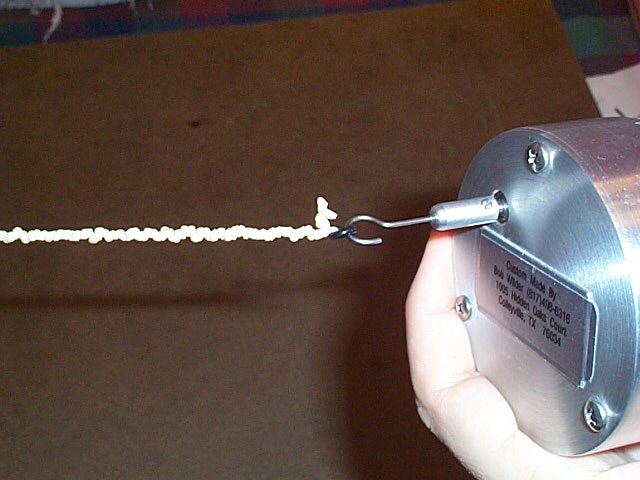

Check

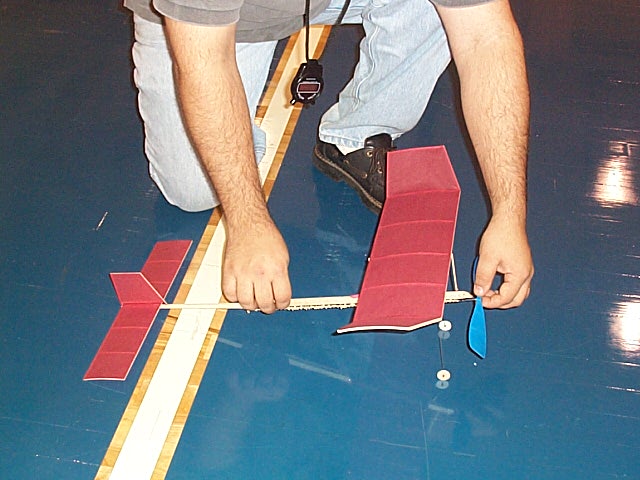

to see if the prop has a little bit of left thrust. See how the right side

of the prop is ahead of the left side in the photo below, this is left

thrust

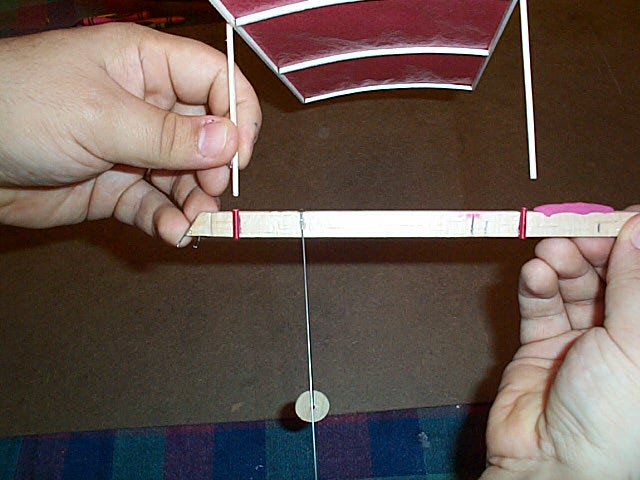

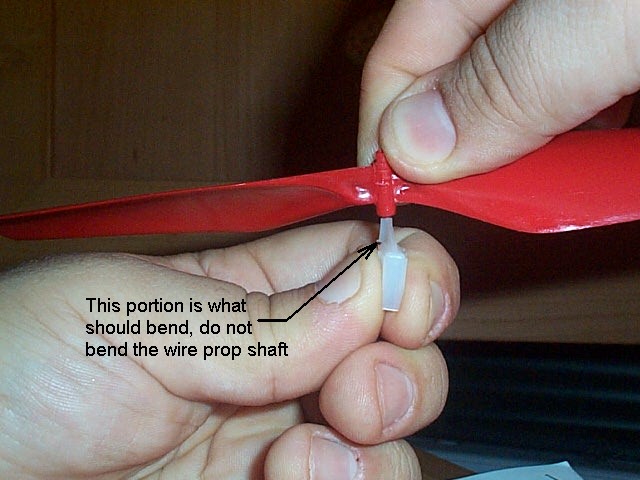

If not, then you will need

to adjust the plastic nose assembly. The method may seen crude, but it

works just fine. Take the prop assembly off of the model and hold it as

shown in the photo, and bend it about 10 degrees to the side. When you

let it go it will bend almost all of the way back, but it should have a

little bit of left thrust now bent into it.

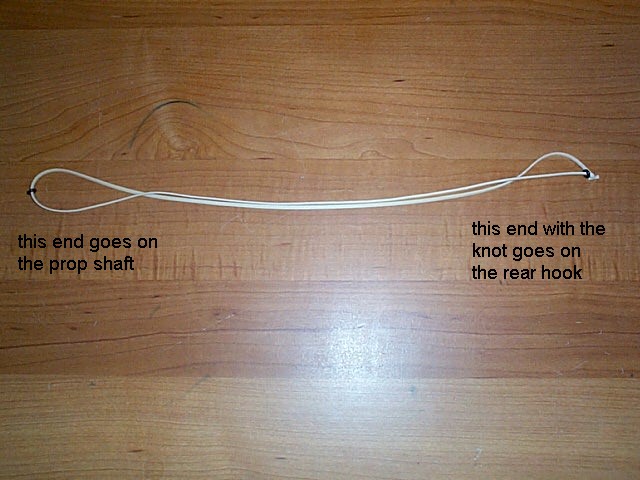

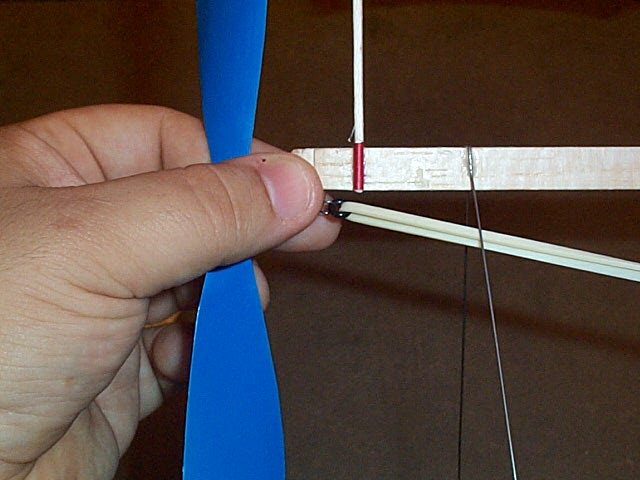

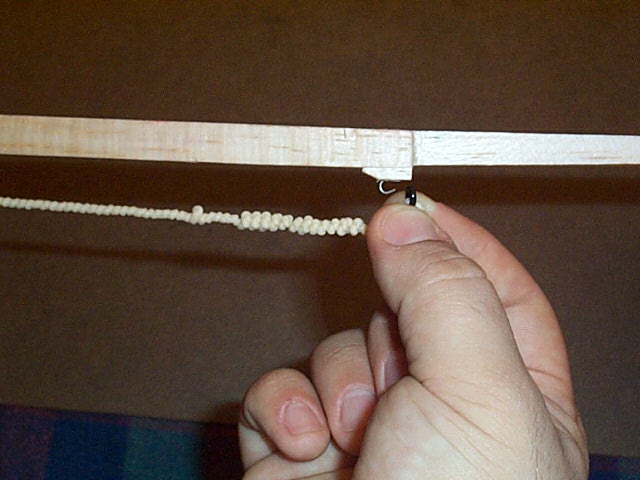

If you do not have a winding

stand, then you will need someone to help you wind your model. If you are

using orings, then you must make sure to slide one o-ring to the back by

the knot and the other forward to the front of the motor. (see photo

below)

Before winding the motor you will want to make sure it is lubricated. The rubber, if unlubricated, will cut and nick itself from its own friction so quickly that it will break within a few uses. However, with the proper lubricant, a motor can be used many times for many years and still perform well. Many people use STP 'Son of a Gun' or other similar protective products since they have high amounts of silicone in them, and silicone is an excellent lubricant for our motors. If you are in a real bind, then a liquid hand soap or liquid dish soap can work as well. Other lubricants that are used by modelers include castor oil, glycerin and greensoap mixtures, as well as other brands of silicone lubricants. In any case, you should always have some lubricant on the motor when winding it otherwise it will not last long at all.

Attach the front o-ring to

the prop shaft hook, and attach the rear o-ring to the hook on the winder.

Have one person hold the

nose of the model securely while the other person holds the winder.

Whoever is holding the model

should use their other hand to shield the model and rubber during winding.

If the rubber should break, it will hit your hand instead of damaging the

wing.

Have the person doing the

winding stretch the rubber about 3 feet away from the model (this is the

out position). For your first flight I would try about 500 turns. The best

winding method I have found is what I call 50/50. What this means is that

50% of the turns are wound in the 'out' position, and then the remaining

50% is wound as you slowly walk towards the model so that when you put

the last turn in you are at the rear motor hook. Once the rubber is wound,

remove it from the winder.

Attach the o-ring to the

rear hook.

You are now wound and ready

to fly.

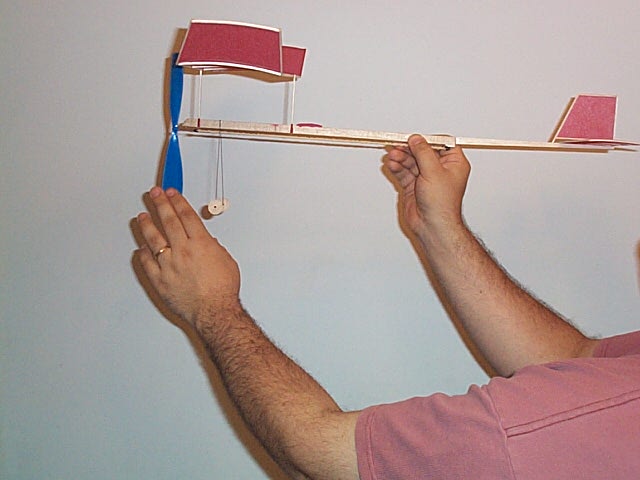

To launch the model, hold

it in one hand by the body behind the wing, and then hold one blade of

the prop with the other. Hold the nose of the model slightly up and then

release the prop,

Once the prop starts spinning, then GENTLY PUSH the model forward with your other hand to get it flying. Watch your model carefully to see what it does, hopefully it will fly just fine but if not then we will have to make some trim adjustments.

If you have a Division C

model and want to have the model take off from the ground, then this is

how you should hold it before launch. To launch it, release the prop, then

release the model, it will take off by itself.

Continue on with trimming the model or back to the main page.